Complete Program Execution

- Simultaneous Engineering / Feasibility Study.

- Conceptual plant layout.

- Part build-up study / Process definition.

- Weld Spot Study / Weld Gun Selection.

- Weld Spot Distribution / Calculation of Cycle Time.

- Design of Geo Tools (Spot/Mig Welding), Re-spot Tools, Grippers.

- Process Validation in Simulation.

- Robot Reachability Study / Robot Payload Check.

- A Simulation Study of the Fixture.

- Manufacturing Drawings and Documentation.

Offshore Delivery Centers

- Customer-Specific Dedicated Facilities With Highly Qualified Engineers.

- Proximity Card-Based Controlled Access With 24x7 Physical And Electronic Monitoring.

- The Dedicated Network and IT Infrastructure Are Completely Isolated For Data Security And Confidentiality.

- Complete intellectual property protection.

- Customized, Knowledge-Based Tools and Guaranteed Productivity Levels.

Onsite Execution

- Compete Responsibility For Highly Interactive Projects Undertaken Directly Onsite At The Customer’s Location.

- High-End Engineers / Program Managers.

- Short-term / long-term assignments.

- Dynamic Resource Management.

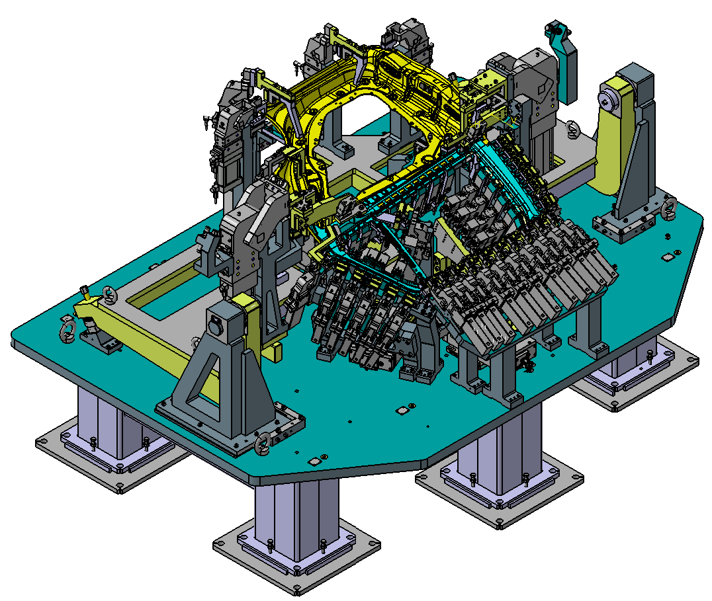

BIW Fixture Design Solution

Suvish ESPL offers high-quality service solutions for BIW Welding Fixtures in the Automotive Industry.

We provide a complete BIW Fixture Design solution for various original equipment manufacturers (OEMs).

Our team has expertise in handling process planning, design, and simulation activities.

Process Planning

- Plant Layout optimization

- Cycle time Calculation

- Weld Points/rivet distribution

- Weld/rivet Gun Selection

- Robot Selection

- Car Part /Panel loading sequence

- Clamping /PLP Plan

- Pneumatic Design

- MTM Analysis

Design

- Geo-Fixtures

- Re-Spot Fixtures

- Material Handling Grippers

- Process & Geo Grippers

- Proto type Fixtures

- MIG Welding Fixtures

- Low Cost Automation (LCA) tooling

- Hemming Fixtures

- Put-Down Stand

- Buffer Stand

- Passing Tables

- Conveyor Tooling

- Gun/Gripper Docking Stand

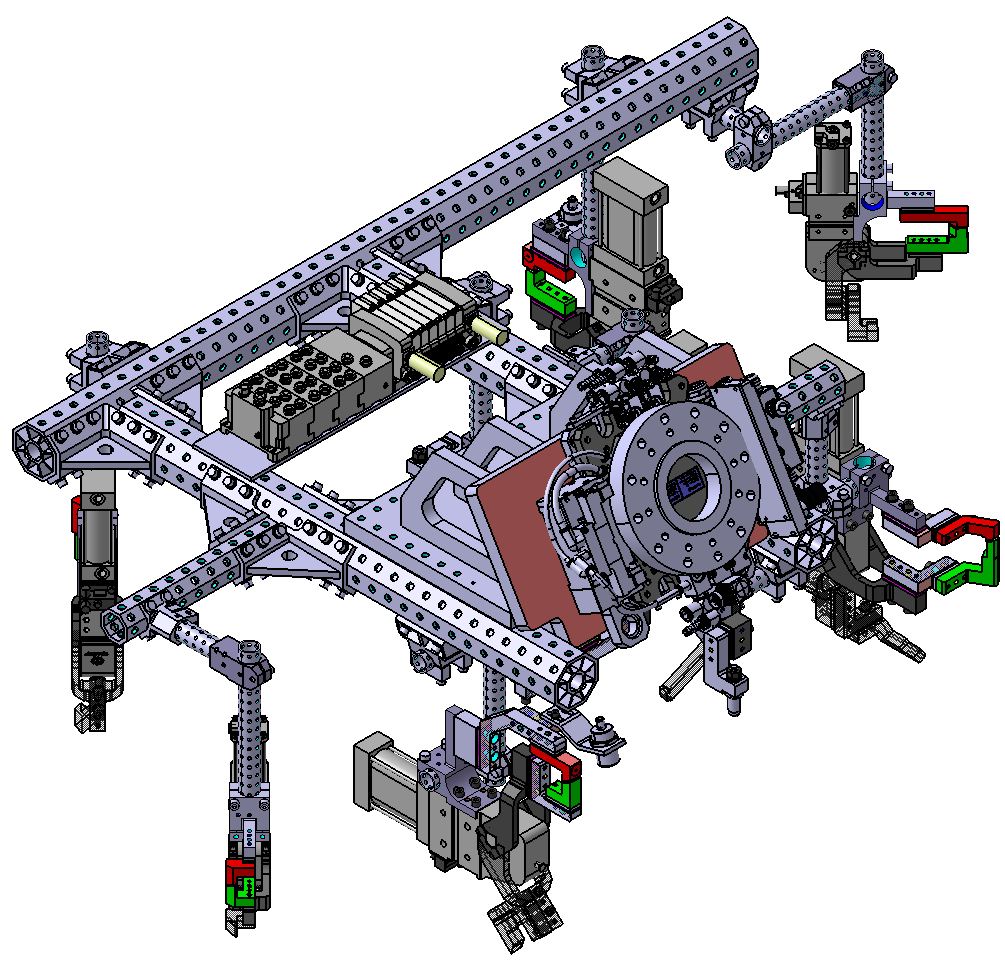

Simulation

- Process Validation

- Robotic Cell Validation

- Weld Spot distribution

- Weld Gun Study

- Robot Selection

- Robot Path Creation

- Operator 's safety and ergonomics

- Operator Safe move zone Creation

- Ofline Programming

- Robot Assembly Drawing

- Foundation Plan

Documentation

- Bill of Material (BOM) in customer specific software

- Gripper Payload (MMI) Validation

- Poke yoke study

- Sequence Sheet

- Shim Plan

- Spot Welding Plan

- Spare & wear part list

- Lubrication plan

- Pueumatic equipment Validation

- Preliminary BOM

- Ergo study

- KIT docunment

Manufacturing Engineering

Manufacturing Design & Development

Part Manufacturing

- Press Tool Design

- Injection Moulding

- Die Castings

- Maschere e dispositivi di lavorazione

- Checking & Inspection Fixtures & Gauges

Automotive Assembly System Designs

- BIW Welding Fixtures

- Chassis Welding Fixtures

- Framing Fixtures

- Hemming Fixtures

- Closures Assembly Fixtures

- Trims Assembly Fixtures

- Assembly / Sub-Assembly Fixtures

- End Of Arm Tooling (Grippers)

- Work Cell Equipments Design

- Assembly Line Equipments

- Conveyors & Pallets

- Material Handling Systems

- Bolting & Riveting Stations

- Layout Planning

Process and Manufacturing Support

Process Engineering

- Pre-Engineering Analysis

- Process Sequencing

- Ergonomics & Reachability

- Layout Planning

Virtual Manufacturing

- Clash Analysis

- Accessibility Study

- Kinematics

- Reachability Study

- Robotic Simulation

- Ergo Analysis

- Cycle Time Optimization & Validation

- Offline Programming

- NC Path Generation

- Sourcing & Supplier Integration

- Production Support

- Onsite Installation Support

- Gestione del cambiamento ingegneristico