Industries Served

Our products are extensively used in pharmaceutical, automotive, plastic and food industries. We also pay detailed attention while choosing our vendors by assessing their previous track records, such as ethical standards, industry experience, technology, methodology, timely delivery and cost effectiveness. Our company is allied with some reputed vendors, who provide us with finest product quality that helps us in serving our clients in an efficient manner. Our vendors utilize advanced machineries and latest technology during the manufacturing process to ensure high quality standards.

- FOOD INDUSTRY

- OIL AND GAS INDUSTRY

- PRINTING & PACKAGING

- AUTOMOBILE

- TEXTILE INDUSTRY

- MANUFACTURING INDUSTRY

- MACHINERY INDUSTRY

- THERMAL POWER

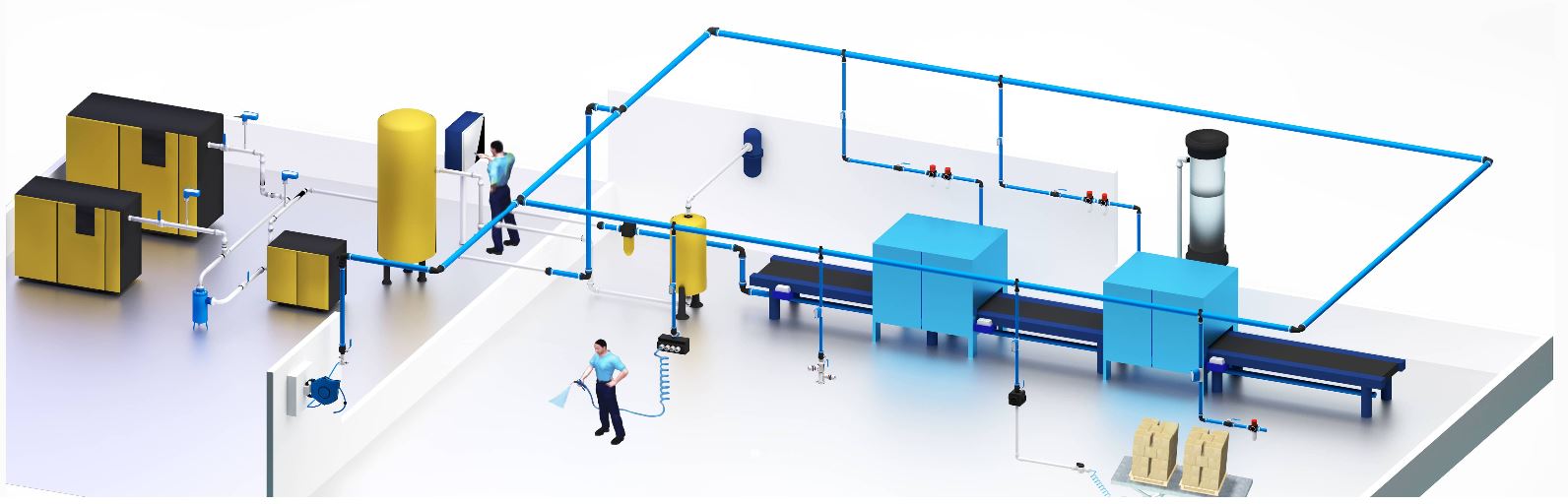

ADVANCE PIPE AND FITTING TECHNOLOGIES

SUVISH works with complete dedication to provide our clients with advanced piping technologies. We provide an extensive range of John Guest / Eqofluids compressed air Aluminum piping which is a push fit fitting system used on all types of pipes. The pipes can be in Aluminum or plastic including Polyurethane, PEX, copper.

The products offered in the pipe solutions applications are as follows :

- Aluminum pipe for compressed air and industrial gases. Aluminum pipe for air compressors is a new concept and is gradually gaining recognition in most of the industries. Due to the non corrosive nature of Aluminum alloy, the pipe retains its surface finish without any scaling or rusting thereby maintaining a very efficient flow rate at a very low pressure drop. For all Pneumatic applications using solenoid valves and Pneumatic cylinders, for e.g. packaging machinery, printing presses, cement bagging machinery, pickling plant for Steel industry, food packaging machinery, pulse sortex machinery, pharmaceutical plants a high efficiency with low downtime is realized with aluminum piping systems.

Non welded piping systems act as a solution to these issues as frequent maintenance can be done due to easy assembly and disassembly of the piping joints without any compromise to the piping layout.

Non threaded piping technology ensures less labor costs, faster turnaround time leading to improvement in project completion schedules. Engineering companies especially engineering consultants in turnkey project contracting prefer to use these systems for efficient project execution and engineering design.

- PEX pipe for plumbing applications. John Guest Speed fit technology using push to fit couplers is a well known technology used by a lot of diy (do it yourself) plumbers, plumbing contractors, plumbing consultants, project engineers, EPC contractors, civil contractors for factory, engineering college, railways, defense. With a 50 year guarantee for a 100% leak proof piping system the applications requiring critical operational parameters under sterile or clean room applications, the NSF certified and FDA approved piping system offers unparalleled performance and reliability.

Where even a single drop of water can wreak havoc to billions of dollars of equipments of they leak, the JG SPEEDFIT system is the answer to these potential problems in piping applications for coolant, pure water, RO water, chilled water and food grade media.

- GI pipe / MS Steel pipe / ERW / seamless steel pipe for water and general gases and fluids.

Conventional piping using Schedule 40 or Schedule 80 GI piping and fittings Or Mild Steel Pipe, ERW / seamless steel pipes and fittings have been used in high volumes for Oil and Gas and welded applications where TIG / Submerged Arc welding / orbital welding / Oxy Acetylene gas welding is applied which needs to be X-rayed and also pressure tested using hydro testing systems at 2-3 times the plant pressure.

This technology comes with its own set of problems as there are Steel Fittings with welded joints which cannot be opened without using gas cutting or grinding. Then the problem of scaling and scale formation due to the hardness of water which has a high content of minerals leading to Lime scale formation.

- Push Fit fittings for connecting pipes of different materials. Metal Couplings eliminate the need to thread or weld pipe. So these fittings for non welded Or non thread piping are very useful and reduce on heavy labour costs incurred using welding consumables and equipments or threading vices.

- Push to Lock fittings for high pressure piping which can go up to 250 bar pressure and can be easily demountable with simple spanners needing less skilled labor and installers.

The entire assortment of products is easy to install and perfect for various compressed air applications. Our professionals design the whole layout according to your precise applications and save up to 50 % time

We offer a specialized array of EQO Fluids High Pressure fittings that has push-in design and works at test pressure of 270 bar and 70 bar operating pressure. Clients can avail these fittings from us in 20 mm to 110 mm diameterFOOD AND AGRICULTURAL INDUSTRIES

- Shurjoint is leading the world with their innovative design and impeccable manufacturing of mechanical piping solutions. Shurjoint has over four decades of experience proving their successful establishment in the agriculture industry.

- The most state of the art piping components accessible today for the agricultural industry featuring efficient and effortless installation, flame resistant safety, adaptability and confirmed reliability and authenticity. Grooved, Hole-cut, Plain-end, Ring Joint, Flanged and Shoulder components for use with a variety of piping materials and service applications including: irrigation, surface / subsurface drainage, closed conduit drainage, fertilization, waterway and more are implemented and provided by Shurjoint.

- SUVISH would be happy to provide help and guidance if they are contacted regarding increased product information. The Shurjoint catalog can also prove to be helpful for your requirements.